Pros:

– Good physical properties:

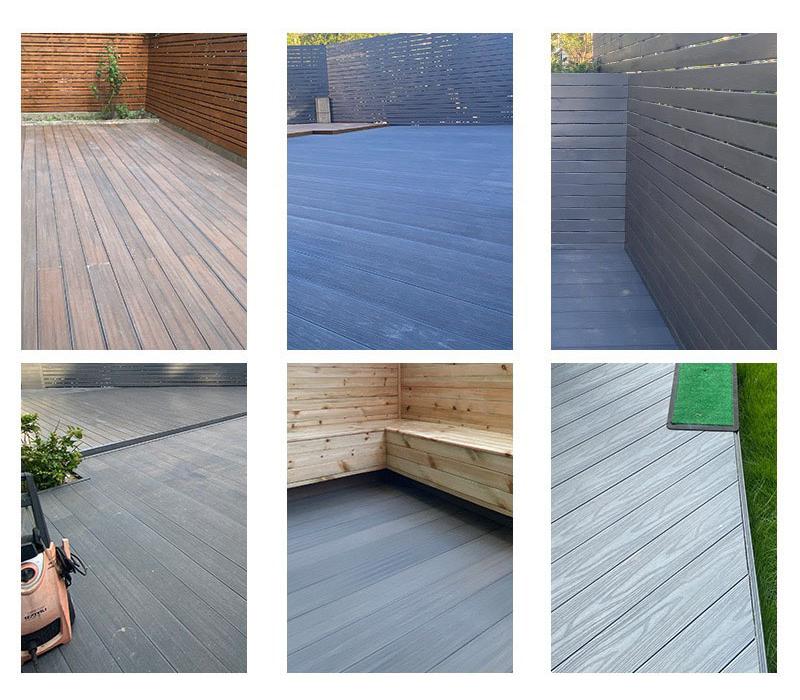

– Waterproof and moisture-proof: the water absorption rate is very low, suitable for outdoor and humid environments, and will not be swollen, deformed, moldy and other problems due to moisture erosion.

– Insects and corrosion: plastic composition and special processing technology makes it can effectively resist the erosion of insects and bacteria, avoiding the shortcomings of the traditional wood is easy to be insects, decay, long service life.

– High stability: it is not easy to be affected by temperature, humidity and other environmental factors, not easy to crack, deformation, in different climatic conditions can maintain good stability.

– High strength: high hardness and strength, able to withstand certain pressure and wear and tear, suitable for places with high traffic.

– Outstanding appearance performance:

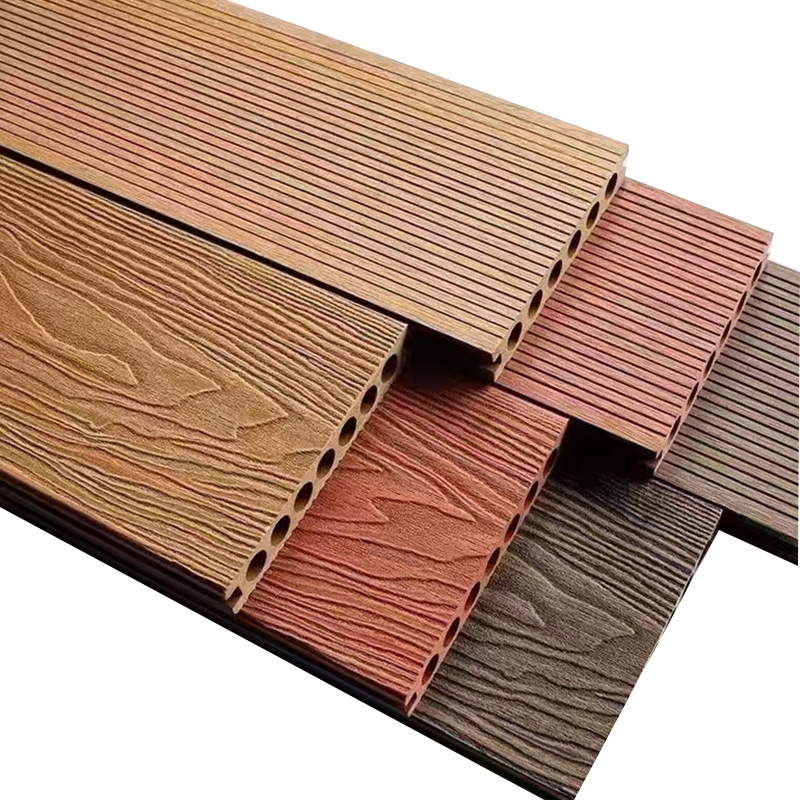

– Rich colors: the floor can be customized with various colors according to different needs and design styles to meet the personalized needs of consumers.

– Realistic texture: through advanced co-extrusion process, it can form realistic wood grain, stone grain and other texture effects on the surface of the floor, similar to the appearance of natural wood or stone, with high decorative properties.

– Good environmental protection:

– Environmentally friendly raw materials: wood fiber and other plant fibers are renewable resources, and the plastic part can also use recycled plastics, which reduces the felling of wood and damage to the environment.

– Processing environmental protection: the production process does not need to use glue and other materials containing formaldehyde and other harmful substances, will not release harmful gases, harmless to human health and the environment.

– Low maintenance cost: basically no special maintenance and upkeep is required during daily use, only regular cleaning is needed, which saves time and energy.

– Easy to install: relatively light weight, easy to carry and install. It can be installed by means of splicing and snap, etc., which does not require complicated tools and techniques, and the construction efficiency is high.

Reviews

There are no reviews yet.